- Total Solutions

- Total Solutions

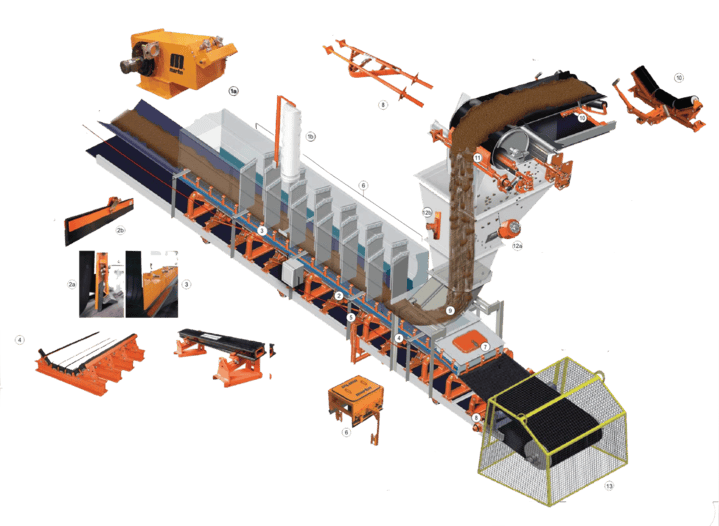

Total Solution, is personalised to match your conveyor, your material and your process requirements.

Martin can provide the assistance required to determine the best course for your operation, through a detailed review of your operation, analyse system problems and performance and submit proposals matching your requirements, wishes and budget

MARTIN DUST COLLECTION SYSTEM

Air filtration - the passing of dust carrying air through some form of filtration or separation system - is the final piece in the dust management system

These are both active and passive dust collection systems.

(1a) Active: Martin air cleaner filters dust-bearing air at transfer point without the duct work or large fans of central bank house systems:

(1b) Passive: Martin dust bag, a passive filtration system, controls dust without power; self cleans by collapsing when air flow stops

PROVIDED AN EFFECTIVE LOW MAINTENANCE CEILING SYSTEM

(2a) Install multiple-barrier Martin Apron Seal Skirting systems to keep cargo away from the belt edge and keep stray particles on the conveyor

(2b) Use Martin self-adjusting Skirting HD to provide and effective seal without maintenance.

PROTECT THE CEILING SYSTEM

(3) Shield sealing strips from the pressure of the load with Martin Ware Liner or Modular External Wear Liner.

CONTROL SPILLAGE

(4) Absorb the impact with Martin Impact Cradles

(5) Stabilise belt path with Martin Idler Conversion Kit

CONTROL AIR SPEED AND DUST WITH LARGER PLENUM

(6) Stilling Zone

Martin Modular Chute Wall System. material load is fully contained; no spillage; no escaping dust. 1-meter sections allow for modular installation and permit later extension of conveyor.

Martin Dust Curtains

Curtains form a barrier, slowing air flow and allowing dust to settle back into cargo

IPMROVE CEILING AT ENTRY

(7) prevent material rollback with Martin Tail Ceiling Box

(8) Martin Tail Protection Plows.

CONTROL BELT SWAY

(9) Martin Belt Tracking Systems. Belt Tracking must be controlled before the spillage can be eliminated.

Control belt sway using Martin Belt Trackers for carrying and return side.

PREVENT CARRY BACK

(10) Martin belt cleaners come in a large array of shapes sizes and materials to most effectively remove and type of material carry back while protecting the belt and its splices

PREVENT BUILDUPS IMPROVE MATERIAL FLOW

(11a) Martin Air Cannons supply a quiet but powerful eruption of compressed air that dislodges buildups and enhances the flow of bulk materials

(11b) The Martin Vibrating Dribble Chute uses an electric vibrator and a low adhesion plastic liner to keep material from clogging chutes and burying belt cleaners