- Primary Belt Cleaners Primary Belt Cleaners

- Primary Belt Cleaners Primary Belt Cleaners

Installed at the point where the belt is leaving the discharge pulley, secondary cleaners remove residual fines that remain on the belt past the primary cleaner. Its location is typically close enough to the materia trajectory that the cleanings will return to the main material stream.

MARTIN® SQC2S MINI CLEANER

◦ Patented rubber buffers maintain cleaning pressure while deflecting to allow splices to pass.

◦ Compact secondary belt cleaner design allows installation in close quarters; narrow profile resists material buildup.

Rubber buffers allow for reversal of belt direction without damage to belt.

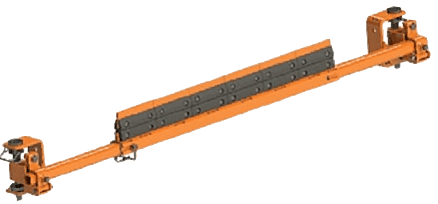

MARTIN® DT HEAVY DUTY SECONDARY CLEANER

MARTIN® DT HEAVY DUTY SECONDARY CLEANER

Installed on a track that slides into cleaning position on a rugged steel mandrel. This unique design makes for a quick and easy service procedure that reduces conveyor downtime and improves productivity.

◦ Slide-in/slide-out blade cartridge allows quick and easy blade service that minimizes conveyor downtime. Even when the cleaner is encrusted with material, one-half of the split frame can be removed to allow blade change.

◦ Blades are made of moulded PU with TC tipped steel backing plate.

Automatic Tensioner provided for more efficient cleaning and easy maintenance

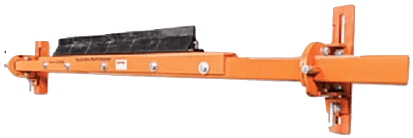

MARTIN® DT STANDARD DUTY CLEANER

MARTIN® DT STANDARD DUTY CLEANER

◦ Slide-in/slide-out blade cartridge allows quick and easy blade service that minimizes conveyor downtime.

Even when the cleaner is encrusted with material, one-half of the split frame can be removed to allow blade change.

◦ Lean profile minimizes space requirements, allows installation in narrow spaces.

Blades are made up of moulded rubber with TC tipped steel backing plate

HIGH-PERFORMANCE URETHANE

HIGH-PERFORMANCE URETHANE

Martin Engineering is the leader in the development of high-performance urethanes for specialized belt cleaner/belt scraper applications. These color-coded urethane blades can be supplied for any Martin® primary cleaner, as well as any primary cleaner supplied by another manufacturer.

Martin belt cleaner blades come in a large array of shapes, sizes and materials to most effectively remove any type of material carryback protecting the belt and its splices. Both metal and non-metal blades are available, including urethane, rubber, ceramic, mild and stainless steels and tungsten carbide.

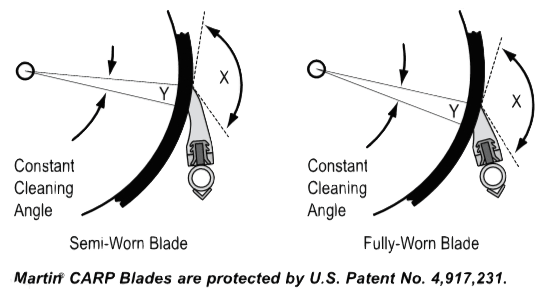

Martin® CARP Blade Design

Patented Constant-Angle/Constant-Area Radial

Pressure blade design. It maintains uniform contact area throughout the life of the blade. This allows the tensioner to maintain proper tension ensuring maximum cleaning efficiency throughout blade life.