- Primary Belt Cleaners Primary Belt Cleaners

- Primary Belt Cleaners Primary Belt Cleaners

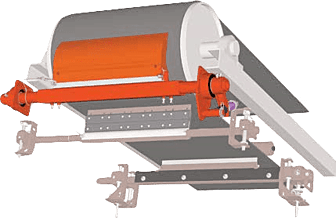

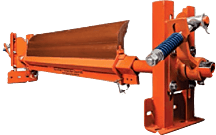

As the first stage in a multiple cleaner system, the primary cleaner removes the majority of material adhered to the belt, leaving only a thin layer of sticky fines.

Primary cleaners are generally tensioned at low pressure— roughly 2 psi (13.8 kPa)—against the belt.

Low blade-to-belt pressure allows the primary cleaner to be positioned at a peeling angle against the belt. The use of higher pressure at this angle would endanger the belt, splice or cleaner itself.

Primary cleaners are typically installed on the face of the head pulley, just below the material trajectory.

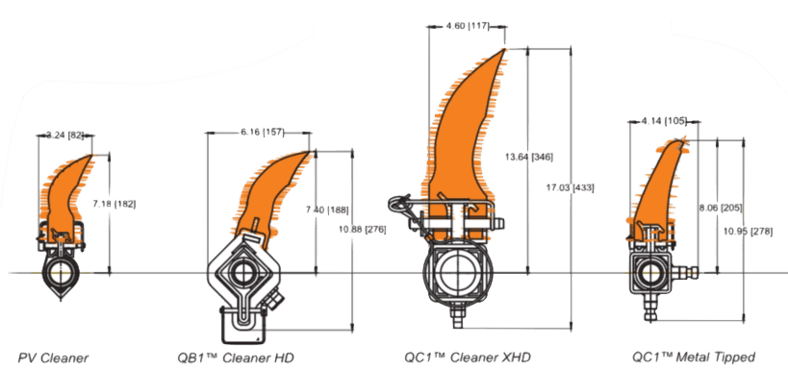

MARTIN® QB1™ CLEANER HD

MARTIN® QB1™ CLEANER HD

The Martin QB1™ Cleaner HD is a patented new evolution in belt cleaner technology designed to help your operation achieve a higher level of productivity while simultaneously reducing costs! It is guaranteed to provide you with the highest performance and the lowest cost of ownership of any urethane precleaner.

◦ Manufactured with Martin's unique Constant Angle Radial Pressure (CARP) technology, its curved blade simply cleans the belt better, minimizing carryback.

◦ Martin re-engineered the manufacturing process, streamlining it to be faster and more efficient, which means your cost to purchase is lower.

The overall cost of maintenance is much less because the blades last longer and blade replacement requires no tools and can be completed by one person in just minutes without tools.

MARTIN® PV CLEANER

The Martin PV Cleaner uses a one-piece urethane blade for effective belt cleaning on aggregate industry conveyor.

◦ One-piece blade contains approximately 20 percent more urethane than comparable primary cleaners, extending service life.

◦ Uses an aggressive angle of attack to the belt to increase cleaning efficiency.

◦ Allows "one-pin, no-tool" blade replacement. drop the sturdy blade into place on the reinforced steel mainframe and secure it with a wire lock pin.

◦ Economical assembly including main frame, urethane blade and tensioner.

Engineered tensioner to ensure optimum blade life

MARTIN QC1™ CLEANER XHD

MARTIN QC1™ CLEANER XHD

The Martin QC1 ™

Cleaner XHD tackles the tough

jobs. Designed for rugged conditions, this sturdy cleaner features a one-pin blade change.

◦ Engineered to preserve the cleaning edge from high belts speeds and multiple splices.

Utilizes engineered tensioner to ensure optimum blade life.

MARTIN® QC1™ PRE-CLEANER WITH METAL TIPPED BLADE

The Martin® QC1™ Pre-Cleaner with Metal Tipped Blade provides maximum durability and performance across a wide range of duties and applications. This sturdy cleaner, qualifies CEMA class 4, features a tungsten carbide tip blade that lasts 2 to 3 times longer than conventional urethane blades

◦ The Martin® QC1 ™ Pre-Cleaner with Metal Tipped Blade combines effective removal of carryback with "quick-change" one-pin replacement of a long lasting blade.

◦ An aluminium extrusion in the belt cleaner blade base holds the cleaner snugly to the Mainframe.

◦ Moulded PU provides cushioning to tungsten tipped Metal blades.

◦ Suitable for max belt speed up to 2.5m/s and should NOT be used on belts with mechanical fasteners and clips

Engineered tensioner to ensure optimum blade life.

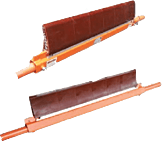

MARTIN® HIGH PERFORMANCE URETHANE BLADE PROFILES