- Wear Solutions For Steel Rolling Applications

- Wear Solutions For Steel Rolling Applications

Application

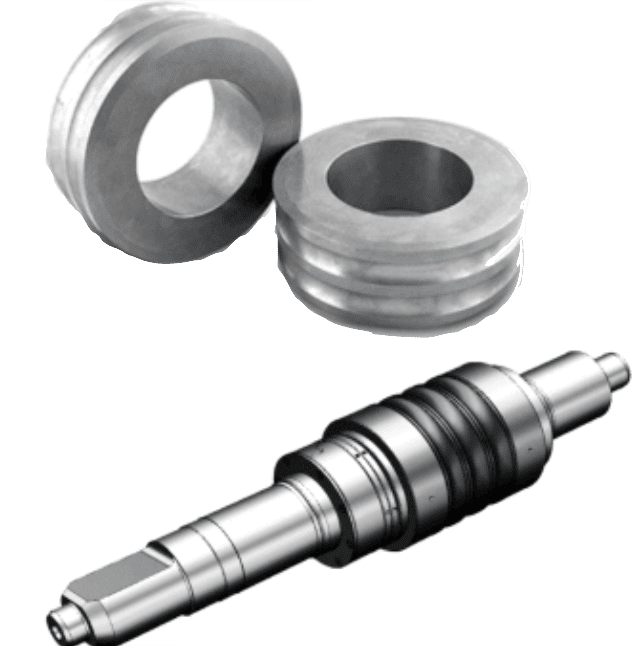

Tungsten carbide is a proven material for many stands in the rolling mill industry.

Tungsten carbide grades developed by Kennametal achieve considerably longer tool lives and improved surface quality for rolls in comparison to cast iron rolls or other materials.

Kennametal tungsten carbide ring grades are characterized by good machinability. To a large extent these tungsten carbides may even be mechanically worked after sintering. Thus the tungsten carbide grades containing binding phase of approx power grain size of approx 25 micron applied for these tungsten carbides proved to deliver the best results for years.

Kennametal India has now become Centre of Excellence for Rolling Mill across the world.

Area of Application

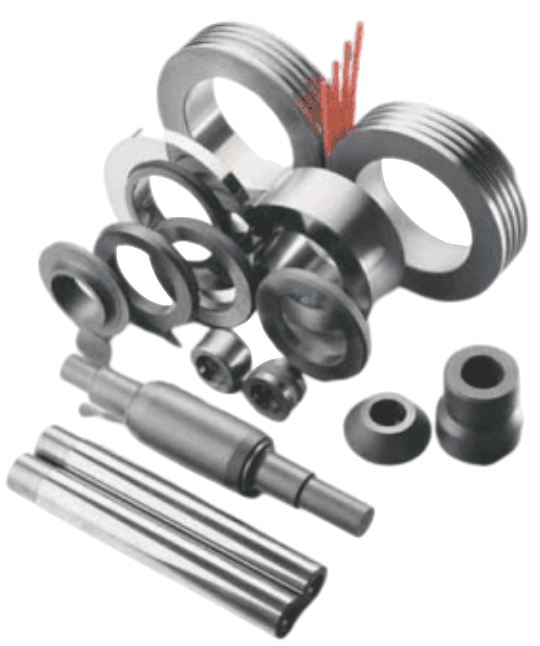

Steel Processing Parts

- Steel Mill Rolls

- Combi Rolls

- Guide Rolls

- Guide Plate

- Tri - Mill Rolls

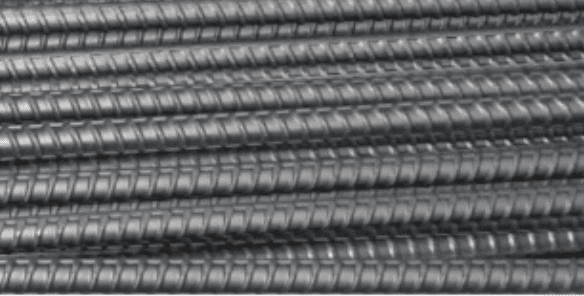

- Cold Ribbed Rolling

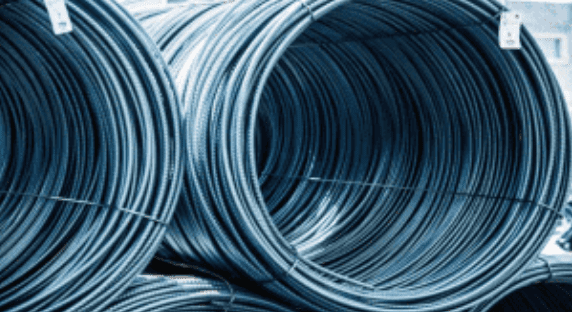

- Rolling Wire

- Cold Forging Parts

- Fastners

- Wire Drawing for various applications

- Rebar/TMT - infrastructure products

Product Availability

- Grades for High Speed mills

- Proven grade in 10, 12, 15, 20, 25 & 30% binder

- Size range upto dia 216mm from India and upto dia 400mm from Germany

- rolls with Grooves for rolls upto dia 216mm

- Technical support